Services

recovering

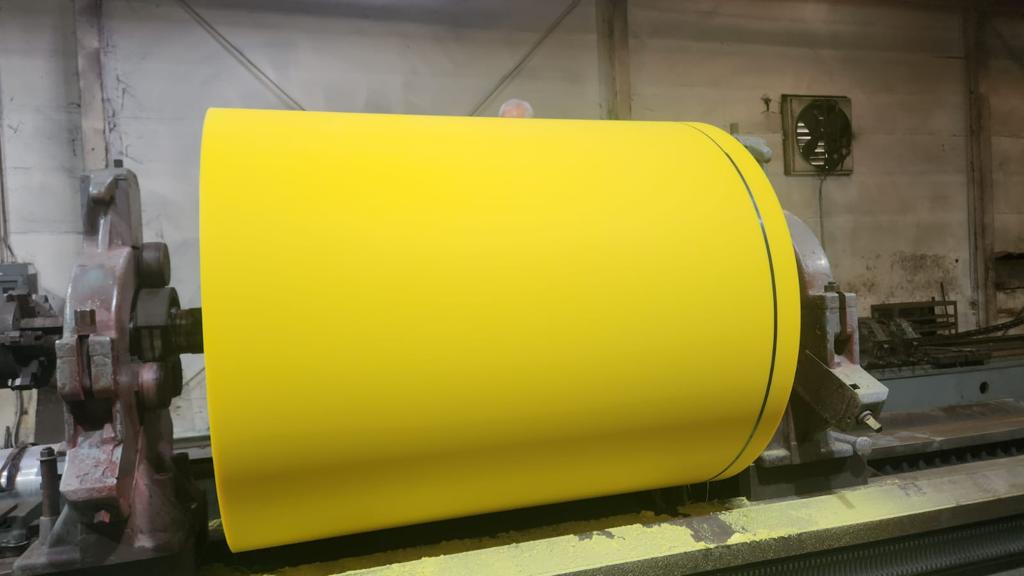

Replacing Worn Coverings Without Replacing the Roller

Recovering replaces worn or damaged roller coverings while preserving the underlying core. This service is ideal when the roller body remains structurally sound, but surface performance has declined due to wear, chemical exposure, or thermal stress.

Recovering also provides an opportunity to upgrade materials or surface characteristics to improve performance.

Covering and Coating Materials

Polyurethane

Polyurethane covers provide excellent wear resistance, load capacity, and traction. They are commonly used where durability, consistent grip, and long service life matter.

Chrome

Chrome coatings create a hard, smooth surface with strong corrosion resistance. They are often used where abrasion resistance and precise surface finish are required.

Ceramic

Ceramic coatings offer extreme hardness, heat resistance, and chemical stability. They are well suited for high-temperature or highly abrasive environments.

Silicone

Silicone covers resist high temperatures and release easily from sticky materials. They are typically used in applications where heat tolerance and non-stick performance are critical.

Tungsten Carbide

Tungsten carbide coatings deliver exceptional wear resistance and surface hardness. They perform well in aggressive, high-wear applications where long coating life is required.

Teflon / Teflon Sleeves

Teflon provides a low-friction, non-stick surface that resists buildup and material adhesion. Sleeves are often used when easy replacement or quick changeovers are needed.

HVOF Carbide Coatings

HVOF-applied carbide coatings create dense, tightly bonded surfaces with high wear resistance. This process is used when coating integrity and long-term performance are priorities.

Felt / Textile Wrap

Felt and textile wraps provide cushioning, absorption, or gentle material handling. They are commonly used in conveying, finishing, or delicate surface contact applications.

Recovering Process

Evaluation, Application, and Verification

Existing coverings are removed and the core is inspected for integrity. New coverings are applied, cured, and finished to specification, followed by final grinding, balancing, and inspection prior to return to service.

Ready to Recover a Roller?

If surface wear is affecting performance but the core remains sound, recovering may be the most efficient solution.

Contact Thistle Roller to discuss your recovering needs.

Lorem Ipsum has been the industry's standard dummy text ever since the 1500s, when an unknown printer took a galley of type and scrambled it to make a type specimen book. It has survived not only five centuries, but also the leap into electronic typesetting, remaining essentially unchanged. It was popularised in the 1960s with the release of Letraset sheets containing Lorem Ipsum passages, and more recently with desktop publishing software like Aldus PageMaker including versions of Lorem Ipsum.

Lorem Ipsum has been the industry's standard dummy text ever since the 1500s, when an unknown printer took a galley of type and scrambled it to make a type specimen book. It has survived not only five centuries, but also the leap into electronic typesetting, remaining essentially unchanged. It was popularised in the 1960s with the release of Letraset sheets containing Lorem Ipsum passages, and more recently with desktop publishing software like Aldus PageMaker including versions of Lorem Ipsum.

Lorem Ipsum has been the industry's standard dummy text ever since the 1500s, when an unknown printer took a galley of type and scrambled it to make a type specimen book. It has survived not only five centuries, but also the leap into electronic typesetting, remaining essentially unchanged. It was popularised in the 1960s with the release of Letraset sheets containing Lorem Ipsum passages, and more recently with desktop publishing software like Aldus PageMaker including versions of Lorem Ipsum.

Lorem Ipsum has been the industry's standard dummy text ever since the 1500s, when an unknown printer took a galley of type and scrambled it to make a type specimen book. It has survived not only five centuries, but also the leap into electronic typesetting, remaining essentially unchanged. It was popularised in the 1960s with the release of Letraset sheets containing Lorem Ipsum passages, and more recently with desktop publishing software like Aldus PageMaker including versions of Lorem Ipsum.

Lorem Ipsum has been the industry's standard dummy text ever since the 1500s, when an unknown printer took a galley of type and scrambled it to make a type specimen book. It has survived not only five centuries, but also the leap into electronic typesetting, remaining essentially unchanged. It was popularised in the 1960s with the release of Letraset sheets containing Lorem Ipsum passages, and more recently with desktop publishing software like Aldus PageMaker including versions of Lorem Ipsum.

Services

Have Questions? Give us a call!

- (562) 948-3705