Capatch

Capatch® – The Disposable Liquid Volume Tester For Anilox Rolls

What is Capatch®

Developed by Steinhart in the Netherlands, the Capatch® is an ink volume tester for anilox rolls.

This one-time tool provides a fast and reliable method of testing rolls to determine the current ink volume level of the cells.

Stop production losses

Capatch is a one-time-use tool that works by contact with the roll as a kind of sticker. A calibrated amount of indicator fluid contained within a capsule on the sticker is forced across the roll under the Capatch sticker when the user runs across the surface with a blade, known as the doctor blade.

The blob of indicator fluid breaks through the front of the capsule and is pushed into the open cells of the roll by the doctor blade. The liquid blob first fills the cells nearest the capsule, decreasing in volume as it is pushed forward, until the entire volume of the blob has vanished into the roll cells. The length of the liquid track determines the current volume of the open cells of the roll. Since the volume of the indicator fluid is constant in all Capatch strips, the length of the track is inversely proportional to the ink, adhesive or coating volume of the roll cells.

Just follow a few simple steps

Available strips

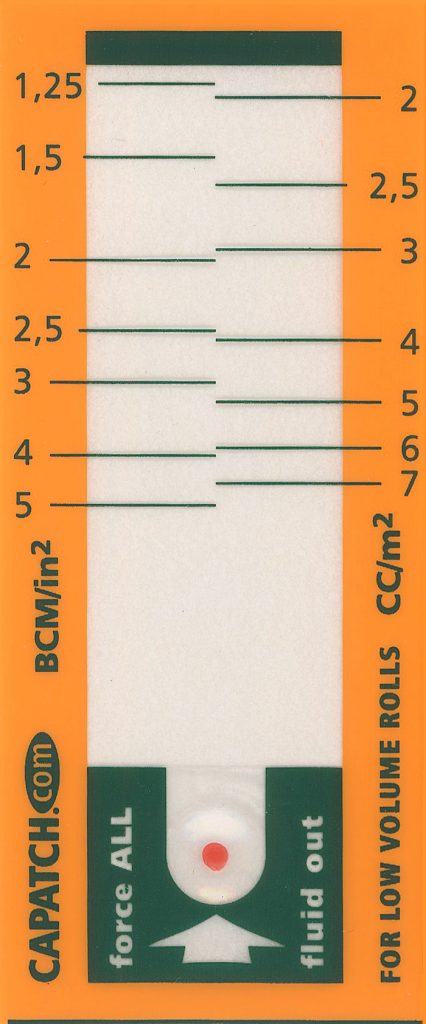

A scale is printed on the Capatch and enables the user to read the volume directly against the track. The strips have different scales or adhesive strength:

Low volume 2 to 7 cc/m2 and 1.25 to 5 BCM/inch2

Low volume 2 to 7 cc/m2 and 1.25 to 5 BCM/inch2

(green – orange strip)

Often used in label printing industry.

Medium volume 5 to 25 cc/m2 and 3 to 15 BCM/inch2

Medium volume 5 to 25 cc/m2 and 3 to 15 BCM/inch2

(dark blue – orange strip)

Often used for rolls with maximum 120 lines.

Often used in corrugated industry.

Medium volume 5 to 25 cc/m2 and 3 to 15 BCM/inch2

Medium volume 5 to 25 cc/m2 and 3 to 15 BCM/inch2

(light blue – orange strip)

Often used for rolls with 120 lines or more.

Often used in flexible packaging and label printing industry.

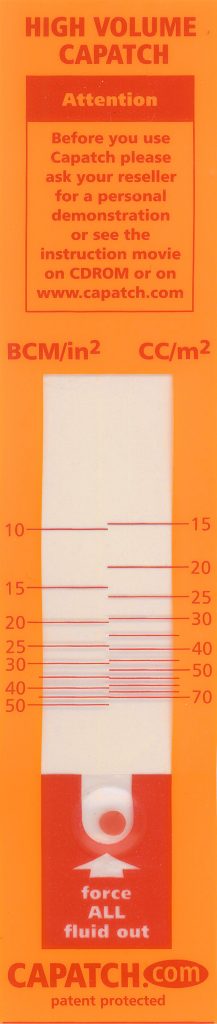

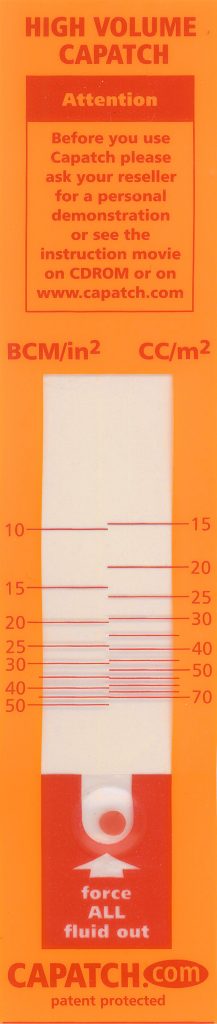

High volume 15 to 70 cc/m2 and 10 to 50 BCM/inch2

High volume 15 to 70 cc/m2 and 10 to 50 BCM/inch2

(red – orange strip)

Often used for rolls to apply adhesives, coating, varnish and similar.

Tri-helical volume 4 to 70 cc/m2 and 2 to 50 BCM/inch2

Tri-helical volume 4 to 70 cc/m2 and 2 to 50 BCM/inch2

(brown – orange strip).

Used for tri-helical rolls.

Compare the results of the test to the roll manufacturer’s bcm.

This will tell you how effectively the roll is performing and should maintenance or cleaning be required.

Use Capatch© To:

- Test the volume of your anilox roll.

- Reduce production downtime.

- Prevent scrap production.

- Schedule roll cleaning.

The Purpose of Capatch®:

The Capatch is “cell pollution trend watcher” and a quick method for measuring volumes of Anilox and Gravure full coating rolls in printing presses. The Capatch has a tolerance of plus or minus 10 percent. Although it might have a similar tolerance to other measurement instruments such as Wyco, Urmi, Ravol and Volugraph, it is not meant to replace them. These methods take 10 to 15 minutes, or longer, to carry out. The Capatch is an additional tool for use in the printing press and gives a rapid reading but with a slightly larger tolerance. It takes no more than two minutes to apply the Capatch correctly.

Call (562) 948-3705 for a sample demonstration or to find out more about cleaning your anilox, rotogravure or laminating rolls.