FEP / PFA Sleeves

Rollers are an integral part of many Paper mill and otherdemanding applications, where minimal downtime is essential.The installation and use of seamless FEP or PFA RollCovers from Saint-Gobainoffers the ultimate in release, corrosion protection, process yield, and reduced downtime.

Saint-Gobain Roll Covers are the largest Seamless Heat Shrink RollCovers in the world featuring the best time-tested surface treatment available for maximum “pull rubber apart” bonding.This provides maximum long lasting adhesion, while maintaining non-stick properties on the outside. Seamless roll covers guarantee uniform construction for the best resistance to stress crack and bond failure even after months and years of tortuous service conditions.

Saint-Gobain is the industry leader in seamless construction of Roll Covers servicing thousands of successful applications. Fast turn around from our large inventory of tubing allows quick reaction to maintenance problems. Custom size Seamless Roll Covers are also available up to 40” (1,016 mm) in diameter in a variety of wall thicknesses for your unique application. Strong “hoop” stress and shrink properties allow for quick and easy installation. Expert assistance or contract field installation is also available. Please consult us for solutions to your specific application.

Applications

PULP AND PAPER

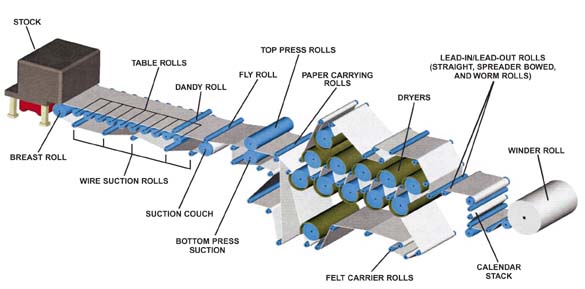

Wet end paper rolls, fly, carrying, lead-in/lead-out, bottom press, suction, calendar, pressure/nip rolls, bowed rolls, grooved rolls.

TEXTILES

Straight and bowed for coating, mercerizing, spinning, dyeing, printing, laminating, finishing, sizing, web spreading, guiding and others.

FOOD & OTHER INDUSTRIES

Food processing, packaging, printing, laminating, packaging, photographic, and many more uses where corrosion, buildup, or sticking of materials is a problem. The Seamless Roll Cover performs in any application where seamless anti-stick technology can eliminate build-up, and protect form corrosive and high temperature environments. Seamless FEP and PFA Roll Covers are made from FDA approved materials.

CUSTOM APPLICATIONS

Larger diameters: On a custom basis, we have the capability of offering a seamless roll cover up to 40” (1,016 mm) in diameter. Different wall thickness: Thickness less than 0.020” (0.5 mm) and up to 0.125” (3.2 mm) can be produced.We will provide specific expansion and shrinkage characteristics for special application requirements. Smaller diameters: Thistle Roller Performance Plastics offers a variety of heat shrinkable products less than 1” (25.4 mm) nominal.

FEATURES & BENEFITS

- Provides a non-stick surface

- Operates in high temperature applications

- Reduces downtime—decreases maintenance due to elimination of material build-up

- Ease of installation—whether sleeves are professionally installed or by your internal personnel, sleeves can be quickly and easily applied during regularly scheduled maintenance.

- Chemical Resistance—FEP and PFA Roll Covers are impervious to virtually all chemicals.

- Increased production—quick release allows for faster roll speed.

- Roll cost reduction—longer life for roll surface, protects from pitting and reduces need to grind.

- Seamless technology—leaves no marks, smooth, consistent surface.

- Chemically Inert—safely used in food industries.

- Excellent flex life/crack resistance, superior flexibility for resilient surfaces, continuous flexing and bowed applications.

- I.D. etching is available for bonding to metal or rubber rollers.

- Zero moisture absorption

- Non-flammable

- High dielectric strength

- Reuse of old rolls

- Manufactured under ISO 9001 guidelines.

- Complete line of sizes—Up to 40 (1,016 mm) diameters, in a variety of wall thicknesses.

- Constructed of FDA approved material.

- Exceptional release and good wear properties give Roll

Cover Sleeves excellent service applications in the food processing industry.

All add up to high value/increased profits.

Saint-Gobain offers etching on the inside diameter for bonding to the roller, whether it is rubber or metal. We recommend bonding the Roll Cover for: rollers larger than 12” (305mm) in diameter, driven rollers, pressure rollers, and rollers of any diameter operating in wet environments or temperatures exceeding 150 (degrees) F (66C).

SEAMLESS FEP & PFA ROLL COVER SLEEVES

TYPICAL PROPERTY VALUES OF NOMINAL FEP AND PFA MATERIAL*

| Property | Standard | FEP | PFA | |

|---|---|---|---|---|

| General | Wall Thickness Aprox. Shrinkage % Shrinkage Temperature Specific Gravity Water Absorption Coefficient of Friction, Dynamic Durometer | D1894 | 0.020" (0.5 mm) 20%-25% 250o F (121oC) to 400o F (204oC) 2.15 0.01% 0.2 53 Shore D | .020" (0.5 mm) 20%-25% 250o F (121oC) to 400o F (204oC) 2.15 0.03% 0.2 53 Shore D |

| Thermal | Melting Point Continuous Service Temp. Coefficient of Linear Thermal Expansion Coefficient of Thermal Conductivity Coefficient Flame Rating | UL746B UL94 | 500o F (260oC) 400o F (204oC) 5.5 x 105 in./in./deg. F (9.4 x 105 mm/mm/deg.C) 1.35 BTU/in/hr/sq.ft./deg.F (0.195 W/m/k) VO | 580o F (304oC) 480o F (249oC) 5.5 x 105 in./in./deg. F (9.4 x 105 mm/mm/deg.C) 1.65 BTU/in/hr/sq.ft./deg.F (0.24 W/m/k) VO |

| Chemical | FEP and PFA Fluorocarbons are chemically inert and solvent resistant to virtually all Chemicals except molten alkali metals, fluorine at elevated temperatures, and certain complex Halogenated compounds such as chlorine trifluoride at elevated temperatures and pressures. | |||

| Mechanical | Tensile Strength (at break) @73o F (23o C) Elongation Flex life, cycles 73 deg. F (23o C) 200 deg. F (93o C) 300 deg. F (149o C) | 3000 psi (21N/nm2) 300% 80,000 80,000 50,000 | 4000 psi (28 N/nm2) 300% 500,000 1,500,000 5,000,000 |

|

| Electrical | Dielectric Constant Volume Resistivity | D150 D257 | 2.1 1 x 105 18 ohm-cm (1 x 105 16 ohm-m) | 2.1 1 x 105 18 ohm-cm (1 x 105 16 ohm-m) |

*Custom applications available

** Standard heat shrink availability.

Thistle Roller Performance Plastics also specializes in custom applications.

Please consult your Sales Representative for details.

| Nominal Roll Cover Diameters** | ||

|---|---|---|

| TubeDiameter | Roll Diameter Range | |

| 1" (25.4 mm) 1.25" (32 mm) 1.5" (38 mm) 2" (51 mm) 2.5" (64 mm) 3" (76 mm) 3.5" (89 mm) 4" (102 mm) 5" (127 mm) 6" (152 mm) 7" (178 mm) 8" (203 mm) 9" (229 mm) 10" (254mm) 12" (305 mm) | 0.88" (22.4 mm) 1" (25.4 mm) 1.3" (33.0 mm) 1.7" (43.2 mm) 2.1" (53.3 mm) 2.6" (66.0 mm) 3.1" (78.7 mm) 3.5" (88.9 mm) 4.3" (109 mm) 5.2" (132 mm) 6.2" (157 mm) 7.2" (183 mm) 8.3" (211 mm) 9.2" (234 mm) 10.6" (269 mm) | 1.08" (27.4 mm) 1.3" (33.0 mm) 1.7" (43.2 mm) 2.1" (53.3 mm) 2.6" (66.0 mm) 3.1" (78.7 mm) 3.5" (88.9 mm) 4.3" (109 mm) 5.2" (132 mm) 6.2" (157 mm) 7.2" (183 mm) 8.3" (211 mm) 9.2" (234 mm) 10.6" (269 mm) 12.1" (307 mm) |